Machine Tool Installation Installs in Menomonee Falls, WI, and Surrounding Areas

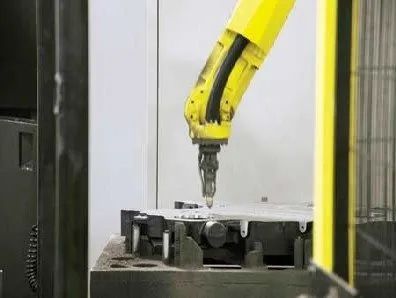

Automation Simplifies Large Part Handling

Stecker Machine Co., Inc. was in search of a solution for machining, deburring, and washing a large casting weighing almost 200 lbs. The part, a large front engine cover for a diesel engine, required a highly accurate and heavy-duty machine to remove metal and hold precise tolerances. The size and weight of the part made handling it difficult and time-consuming for an operator. Stecker's list of requirements for the task included:

- Allows for ergonomic considerations to eliminate the risk of injury to employees.

- Minimize output variation that can often result from manual handling of large parts.

- Develop a deburring system that will be automated and consistent to meet customer specifications and keep the operator available to maintain other areas of the cell.

- Develop the most cost-effective production solution to meet customer requirements and allow for fluctuations that may exceed initial projections.

- Identify a parts washer solution that would remove all debris after machining to provide consistently clean parts.

It was determined early in the project that new equipment would be required and that a robotic solution would be the best fit. The 800 mm- and 630 mm-sized horizontal machining centers (HMCs) were both considered for machining. The solution selected was two new Toyoda FH630SXs with 8,000 RPM and 50 HP high-torque (744 ft-lb) spindles, which would allow heavy-duty metal removal and high accuracies. With the large envelope of the FH630SX, Stecker was able to fit the part into the machine without moving up to an 800 mm-sized machine.

For all your questions and more, call our team today at 262-786-6570.